My Rainbow Lynx: 3D printed PLA and Aluminium

A 4-Victory for BritNerf's Secret Santa 2021

Argos: A high-powered, brassed Firestrike

A Green Doublestrike

A Pink Doublestrike

Doomthorn: A minimised, brassed, doublestrike

Bicep: My first mod, a strongarm with spring upgrade, swappable cylinders, and an integrated flashlight

Featured vinyl stickers and gold paint

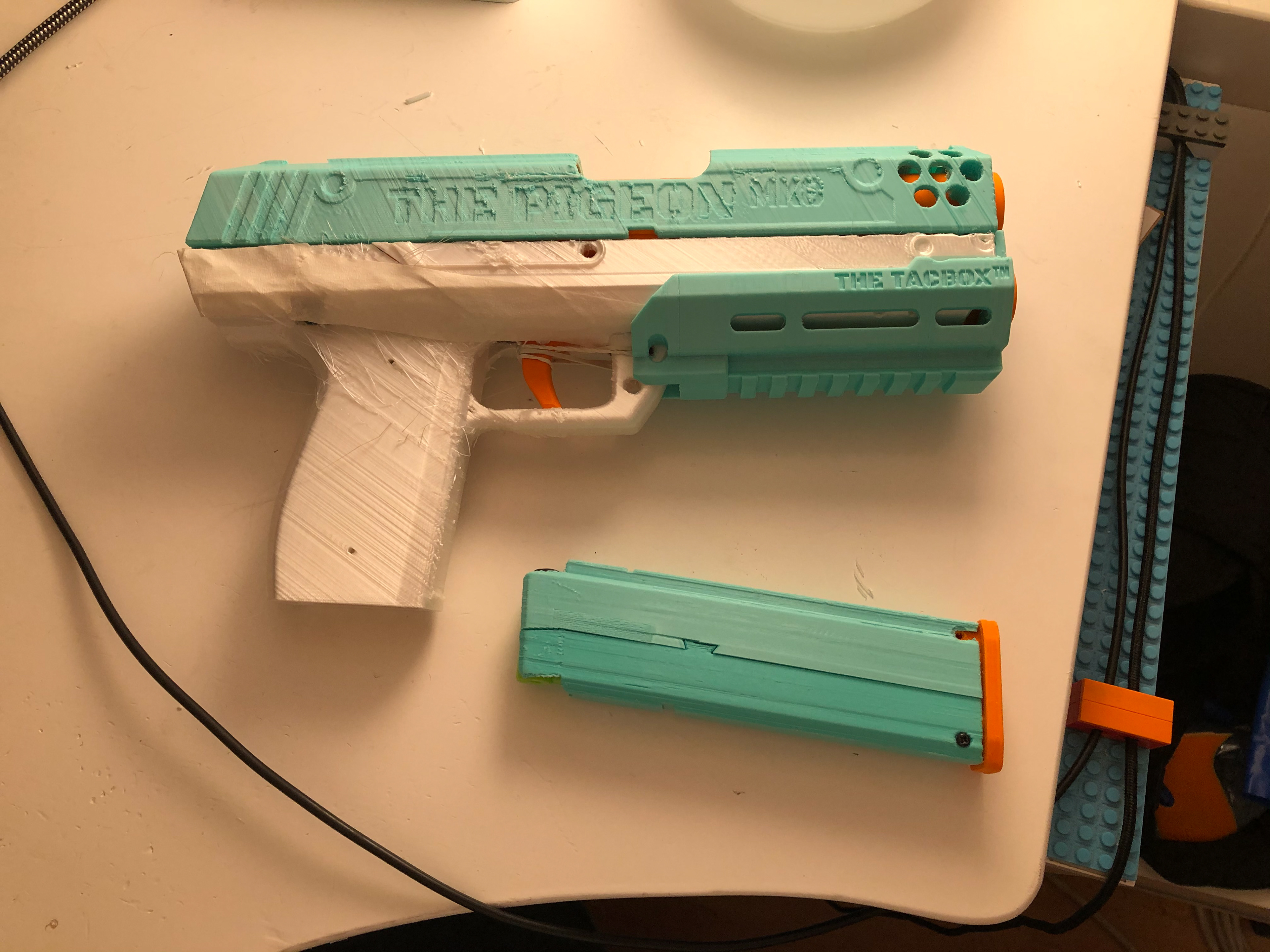

The Dessert Pigeon

One of my more obscure hobbies, modifying foam-flinging "Nerf" blasters has been a great way for me to relax and have fun through sports, engineering and art.

On simple aesthetic mods like the pair of Doublestrikes and the 4-Victory, I focus on the paint job, detailing, ergonomics and the fictional story behind the blaster. With builds such as the Lynx or Strongarm, I focus on the performance, maximising the velocity, range and accuracy of the blaster.

Springer builds are akin to pneumatic systems, and usually have spring-powered plunger tubes leading to barrels for the darts. Modifications to these often consist of upgrading the spring and catch mechanism, and "brassing" the barrel so that it fits the dart with a perfect tolerance and doesn't let air escape. The Lynx uses a unique "turnaround" system where the plunger moves backwards, and pushes air through a 180° U-bend into the barrel; meaning the blaster has a very long barrel whilst remaining compact in its overall length.

Most electronic blasters use a pair of motorised flywheels, through which a dart is pushed and accelerated. My Dessert Pigeon is a fully 3D printed blaster that uses a 2s LiPO to power 2 high-torque motors which fire half-length darts through the flywheels.

3D printing is often used in the blaster modding hobby, and whilst I have designed a few of my own fully-printed blasters I haven't had the chance to realise them as yet. I have designed and printed a few accessories for various blasters, as well as printing and building a Lynx, which was designed by Orion Blasters in the US.