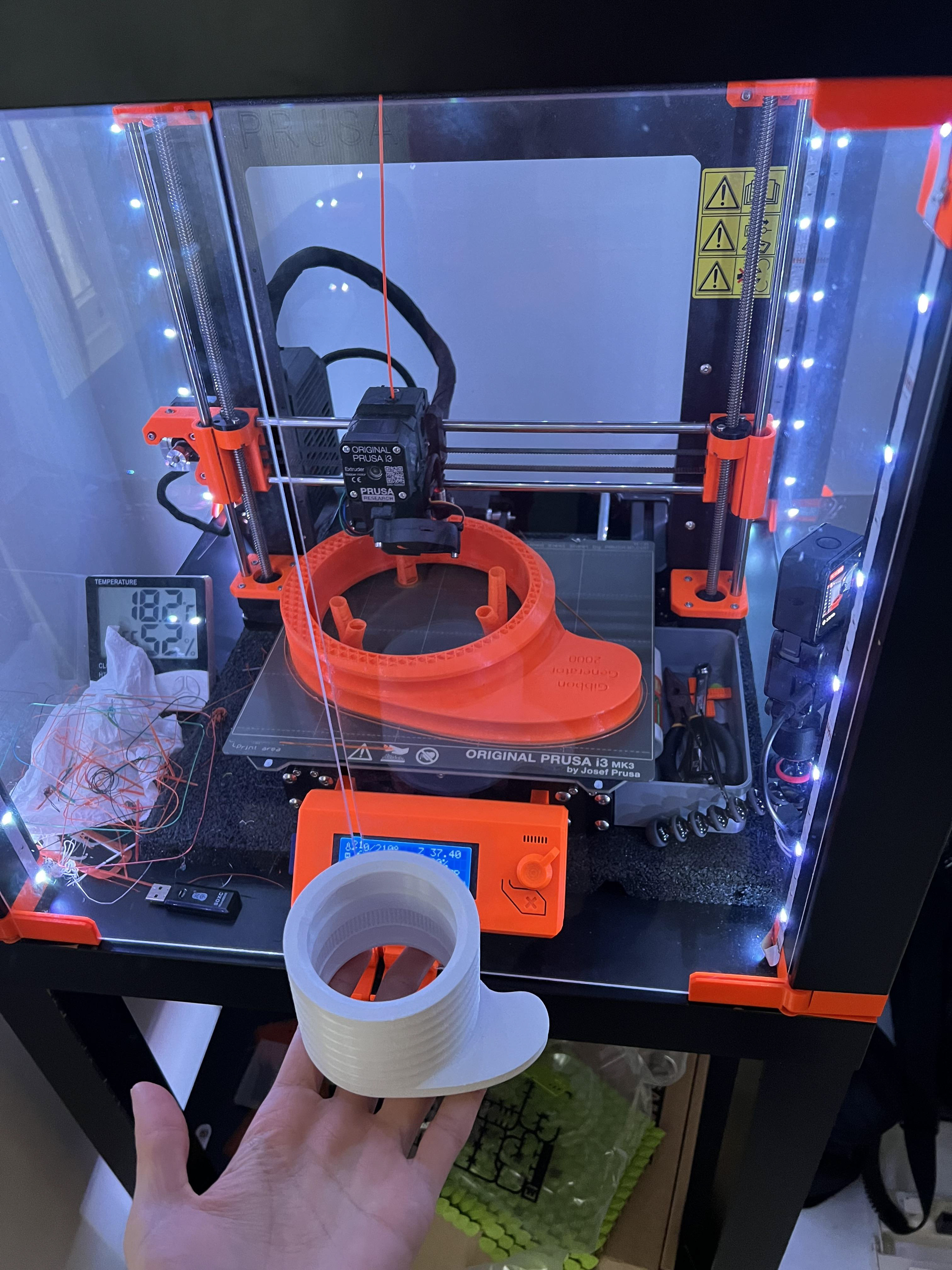

I have been involved in 3D printing for around 10 years now. I am currently leading a printing service for the Mech Eng undergraduates at Imperial, where I had a mini lecture series on introductory 3D printing and currently act as an advisor to student projects. My current personal printer at home is a Prusa MK3S, which is an absolute workhorse of a machine!

My passion for the technology started in primary school with an amazing Design and Technology (and Magic) teacher, and a lecture I gave in Year 6 about the subject. I started saving there and then for my very own 3D printer, a Geeetech A10M, which I was lucky enough to buy 4 years later in 2020. It was perfect for keeping my 'innovative juices' flowing during the otherwise boring lockdown, and it was then that I first came to understand and love the iterative design process.

My experience came in useful at school, where I helped to build and run a small fleet of Creality CR10s for student projects. I also learned how to use SLA printers, namely the Formlabs Form 2 and 3, which were amazing for high-quality display prints. Some of my largest prints (40+ hours) were CFRP layup moulds printed on the CR10s at school for my exoskeleton project.

I enjoy using 3D printing for small around-the-house improvements and repairs. Using Fusion 360 for all my 3D CAD is very quick and has allowed me to complete many 1-day or few-hour projects including wall planters, storage hooks for an IKEA modular system and small toys and gimmicks as gifts for friends. 3D printing is a brilliant method for iterative design too, as it allows for the creation of multiple iterations within a day; this is massively useful when rapidly developing parts for competitions or mini-projects.

As well as a tool for idea creation, 3D printing has itself become a hobby for me. With printer upgrades and repairs, filament tuning and testing the strength of different print-orientations, there are so many aspects to explore within the 3D printing hobby. I often use Thingiverse and Printables to find test-prints and fun things to make without having to design them myself; and you can check out my own collections here.

(Note: Most of these images are quite old, I will upload some recent pictures soon)

A vase from thingiverse

A working prototype of a modular speaker and amplifier connecting with magnetic contacts

My mask deployment system

My deployable/retractable face-mask

The many iterations of EDITH hinges

SLA Spiderman Web-Shooter

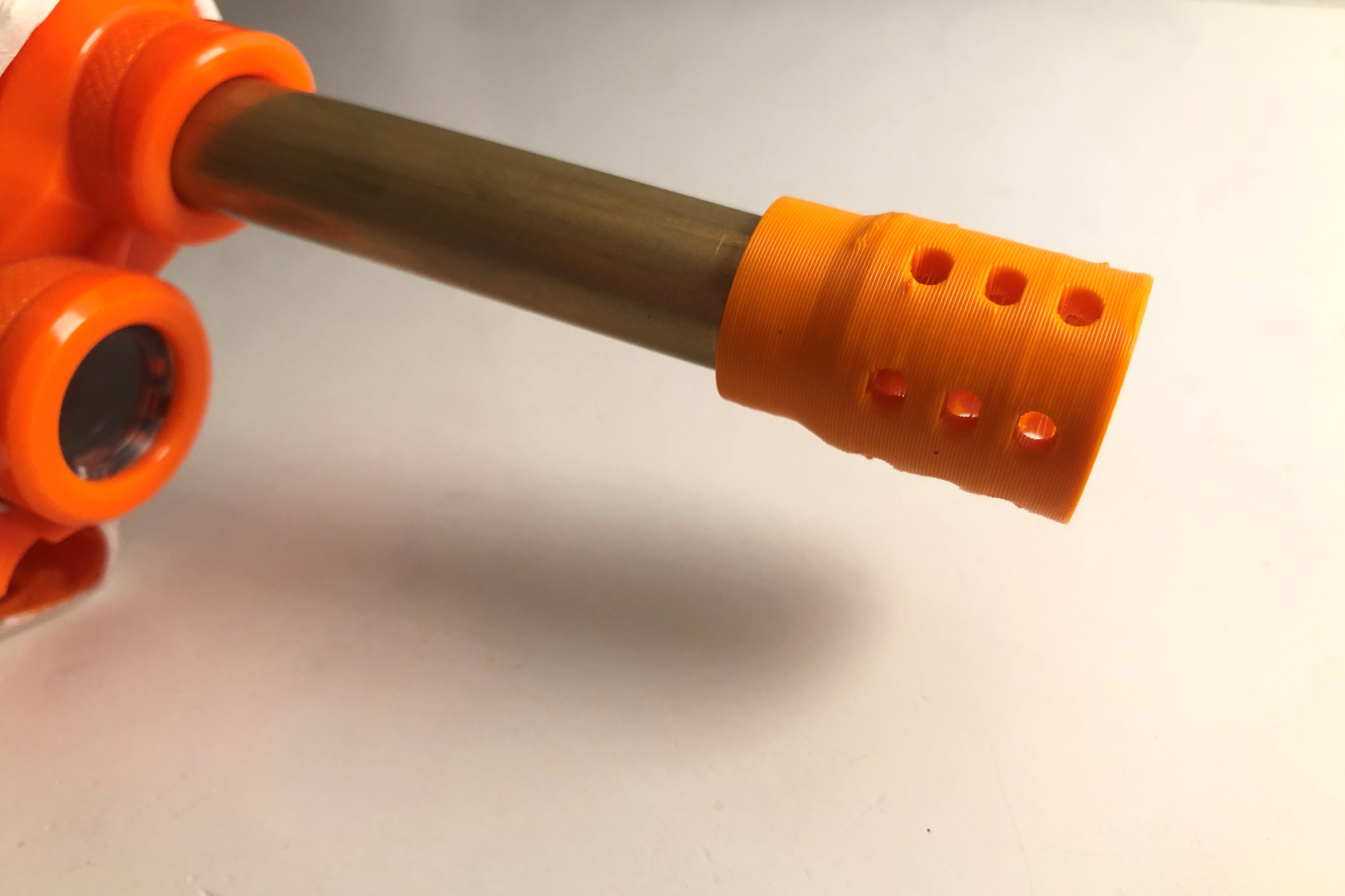

A brass barrel cover "1-hour project"

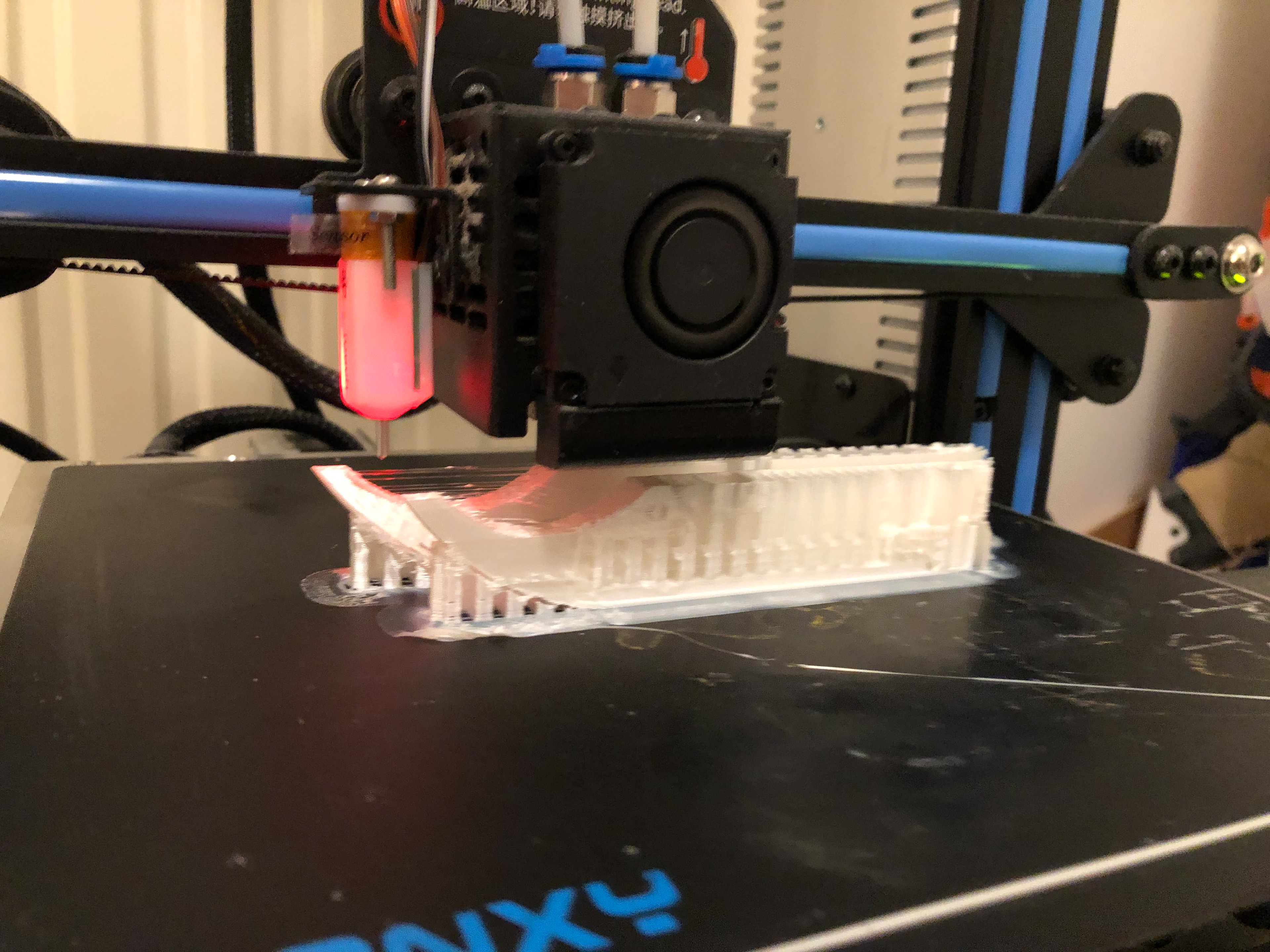

My printer in action, making a set of EDITH's arms

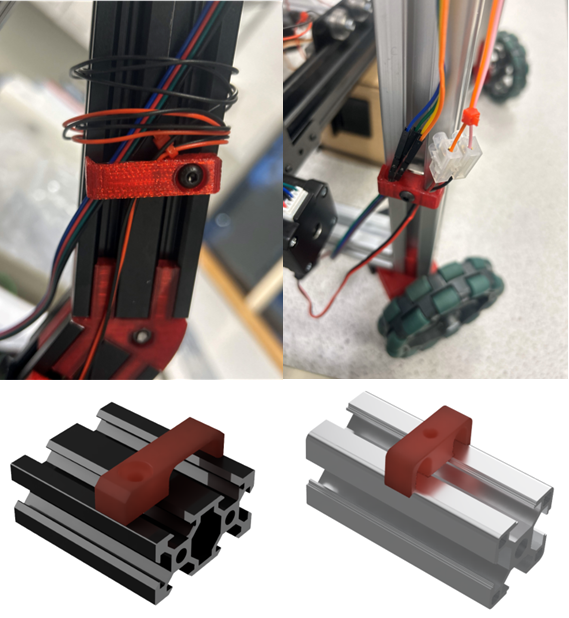

Cable management for robotics

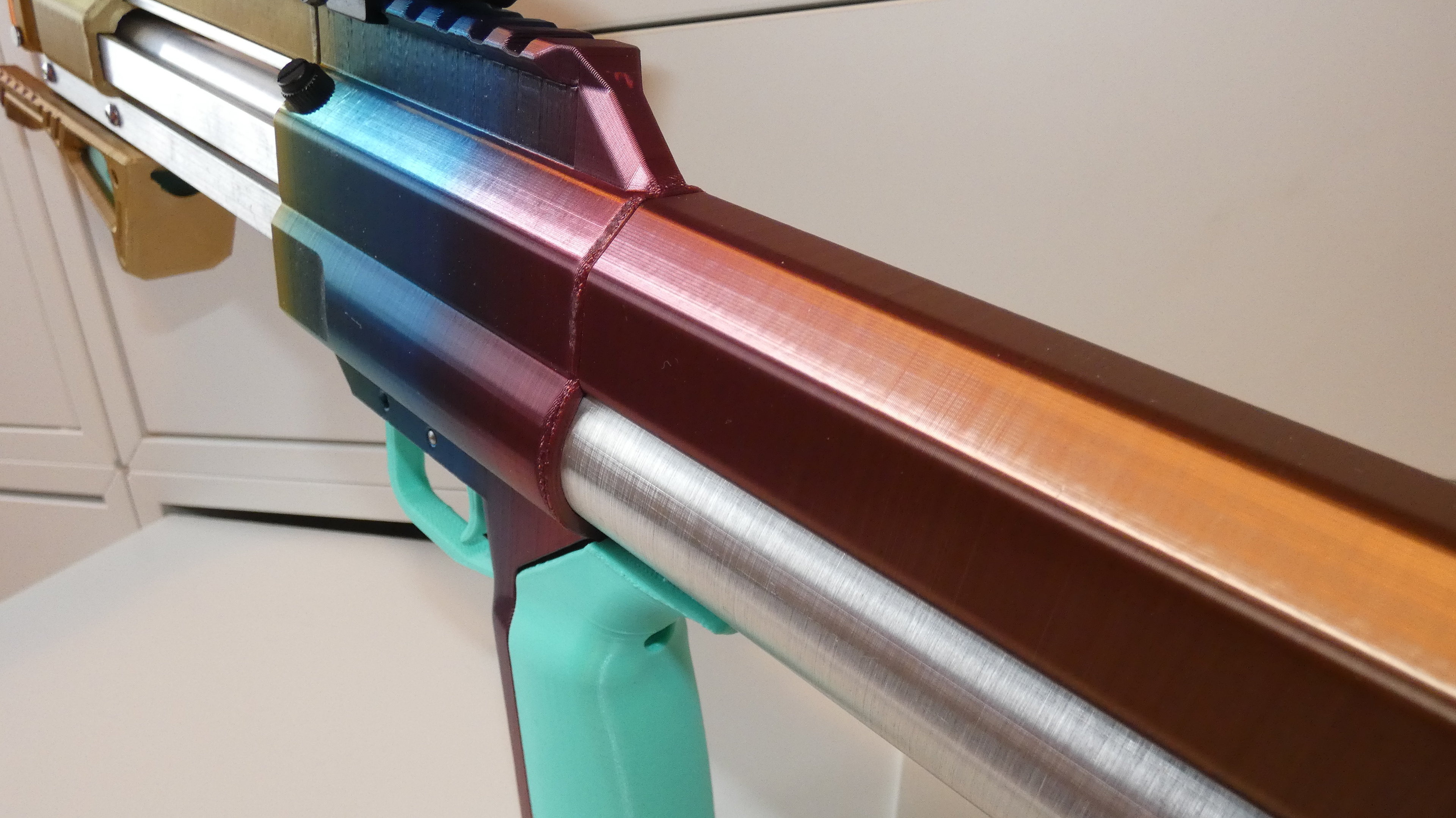

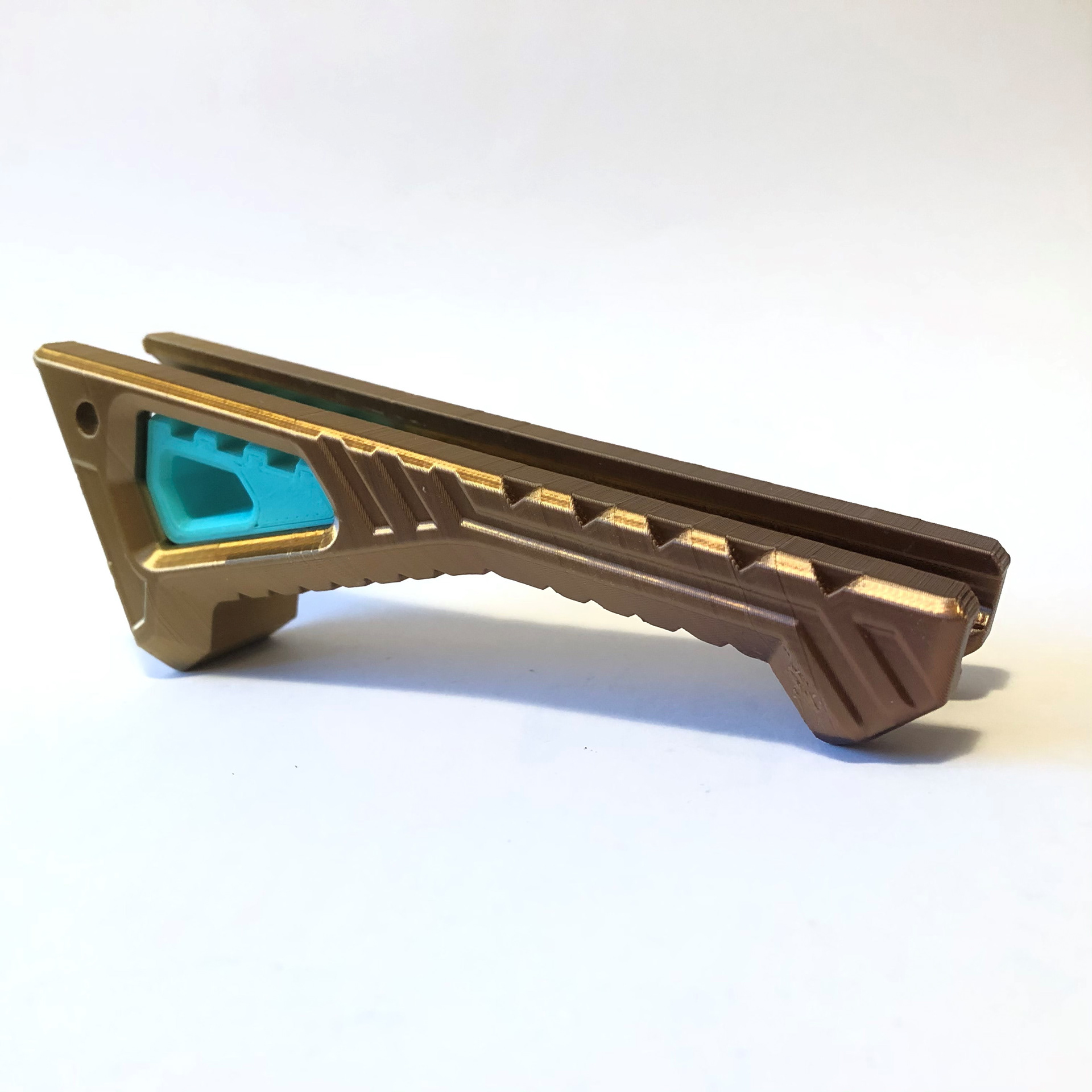

Nerf Blaster Foregrip (Captain Slug)

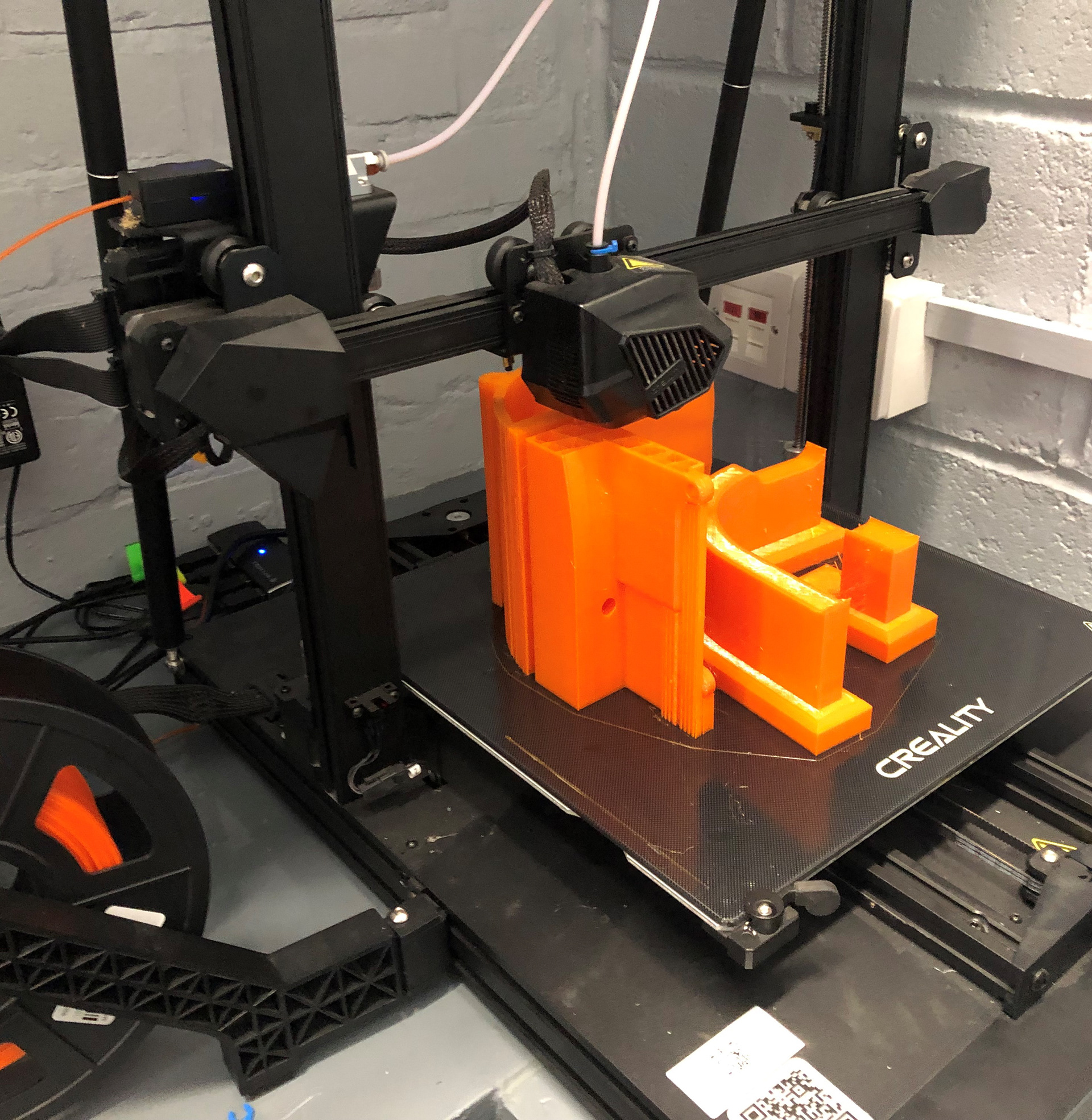

Printing a PETG carbon fibre compression-mould

All-in-one fins and engine holder for model rocket

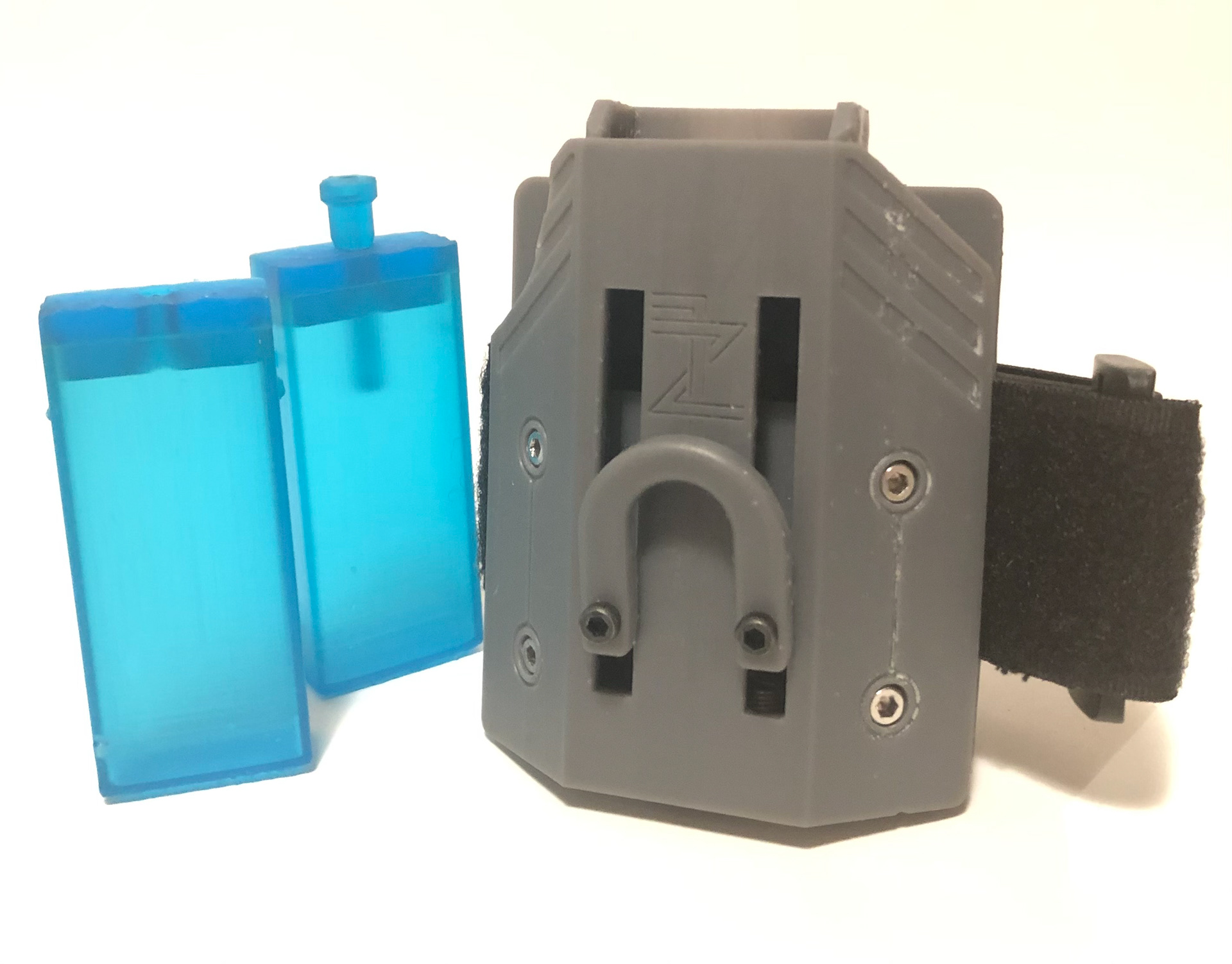

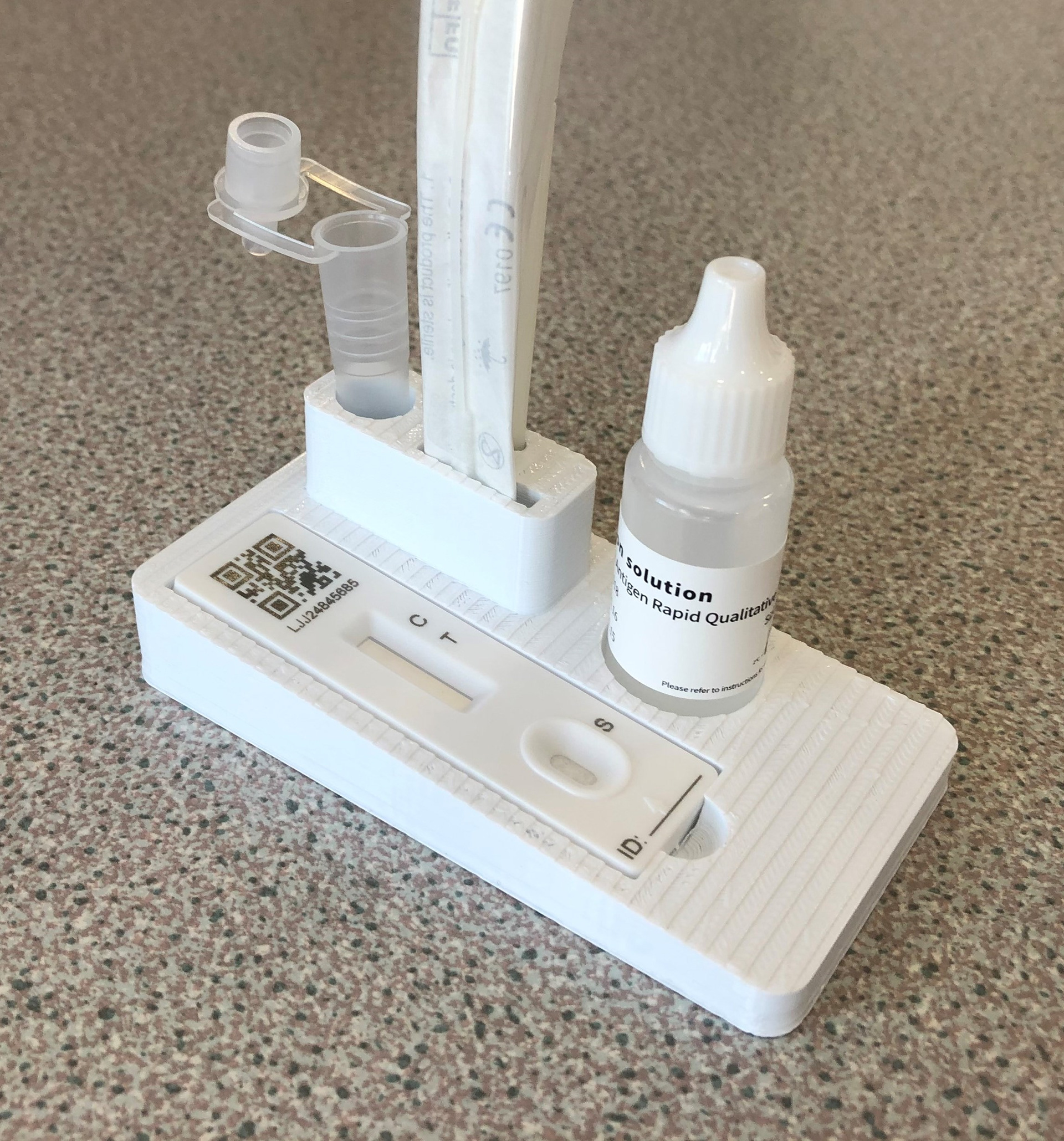

Lateral Flow Test Holder